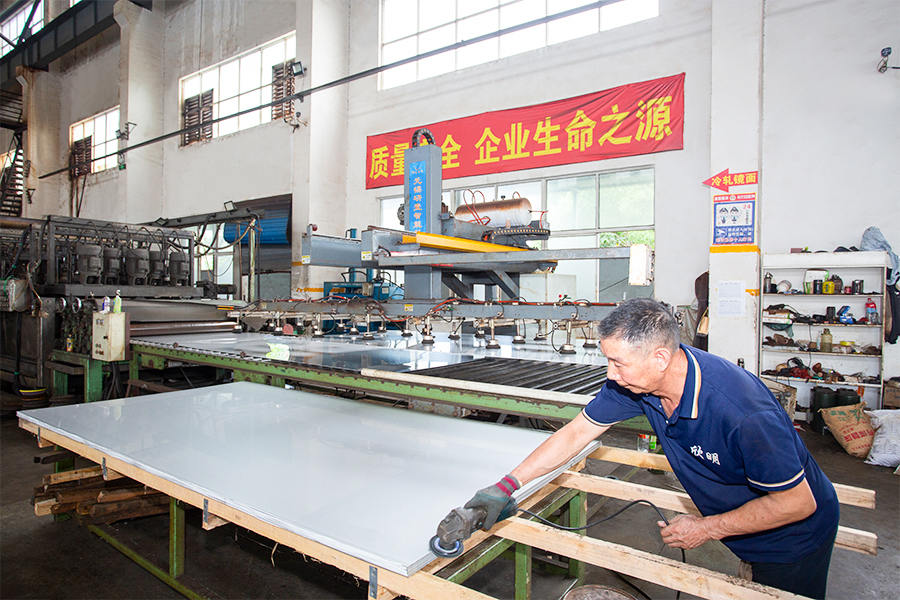

In the world of industrial manufacturing, construction, and precision engineering, the quality of raw materials directly impacts the strength, durability, and performance of the final product. Among the most essential and widely used materials in modern industry is the Cold Rolled Flat Plate—a high-precision steel product renowned for its superior surface finish, dimensional accuracy, and enhanced mechanical properties.

Whether used in automotive components, machinery fabrication, electrical enclosures, or architectural applications, cold rolled flat plate steel offers unmatched consistency and reliability. Unlike hot rolled steel, which is formed at high temperatures and may exhibit scale and slight dimensional variance, cold rolled flat plate undergoes a secondary processing technique at room temperature that refines its structure and elevates its performance.

In this comprehensive, SEO-optimized article, we’ll explore what cold rolled flat plate is, how it’s made, its key advantages, common applications, and why it has become the preferred choice for industries that demand precision, strength, and a premium surface finish.

What Is Cold Rolled Flat Plate?

Cold rolled flat plate refers to steel plate that has been processed through a series of rolling mills at ambient temperature—after initial hot rolling—to achieve tighter thickness tolerances, improved surface quality, and increased strength. Typically available in thicknesses ranging from 0.5 mm to 6 mm (though thicker plates can be cold finished), these flat sheets are characterized by their smooth, scale-free surface, uniform edges, and excellent formability.

The term “cold rolled” indicates that the material is shaped without the use of heat, allowing for greater control over the final dimensions and mechanical properties. This process not only enhances the steel’s tensile strength but also improves its hardness and surface finish—making it ideal for applications where aesthetics, precision, and structural integrity are critical.

Cold rolled flat plates are most commonly made from low-carbon steel (such as C1008 or C1010), but can also be produced using medium-carbon or alloy steels depending on the required strength and application.

How Is Cold Rolled Flat Plate Manufactured?

The production of cold rolled flat plate is a multi-stage process designed to refine the steel’s properties:

Hot Rolling: The steel is first heated above its recrystallization temperature and rolled into rough plates or coils.

Pickling: The hot rolled steel is treated with acid to remove the iron oxide (scale) that forms during high-temperature processing.

Cold Rolling: The descaled steel is passed through a series of precision rollers at room temperature. This reduces thickness, improves flatness, and increases density and strength through work hardening.

Annealing (Optional): To restore ductility, the steel may be annealed—slowly heated and cooled—in a controlled atmosphere.

Skin Passing or Temper Rolling: A final light pass through the rollers ensures flatness, improves surface finish, and eliminates yield point elongation.

Cutting and Finishing: The steel is cut to size, oiled to prevent rust, and packaged for shipment.

This meticulous process results in a product with tight thickness tolerances (±0.05 mm or better), a bright, smooth surface, and consistent mechanical properties across the entire plate.

Key Advantages of Cold Rolled Flat Plate

One of the primary reasons cold rolled flat plate is favored across industries is its superior performance compared to hot rolled alternatives.

Exceptional Surface Finish

The absence of mill scale and the smooth, clean surface make cold rolled flat plate ideal for painting, plating, or powder coating. It’s often used in visible components where appearance matters.

High Dimensional Accuracy

With precise thickness control and minimal warping, cold rolled plates are perfect for CNC machining, laser cutting, and automated fabrication processes.

Increased Strength and Hardness

The cold working process increases the steel’s yield and tensile strength, making it more resistant to deformation under load.

Improved Formability and Weldability

Despite its higher strength, cold rolled steel maintains good ductility and can be easily bent, stamped, or welded without cracking—especially when annealed.

Consistent Quality

Produced under strict quality control, cold rolled flat plates offer uniform grain structure and predictable performance, reducing the risk of defects in final products.

Better Aesthetic Appeal

Its clean, shiny surface gives it a more professional appearance, making it suitable for consumer-facing products like appliances, furniture, and electronic housings.

Common Applications of Cold Rolled Flat Plate

The precision and reliability of cold rolled flat plate make it indispensable across a wide range of industries:

Automotive Manufacturing

Used in chassis components, brackets, panels, and interior structural parts where dimensional accuracy and strength are essential.

Machinery and Equipment Fabrication

Ideal for gears, shafts, frames, and housings that require tight tolerances and smooth finishes for optimal performance.

Electrical and Electronic Enclosures

Preferred for control panels, switchgear, and server racks due to its flatness, weldability, and ability to accept protective coatings.

Appliances and Consumer Goods

Found in refrigerators, washing machines, ovens, and HVAC units—where both function and appearance are important.

Construction and Architectural Elements

Used in precision brackets, support beams, and decorative metalwork that require clean edges and smooth surfaces.

Metal Stamping and Pressing

Widely used in high-volume stamping operations for producing small, intricate parts with consistent quality.

Furniture and Shelving

Chosen for modern metal furniture, display units, and industrial shelving due to its strength and sleek finish.

Cold Rolled vs. Hot Rolled: Why Choose Cold?

While hot rolled steel is more economical and suitable for heavy structural applications, cold rolled flat plate offers distinct advantages when precision is required:

Tighter Tolerances: Cold rolled steel maintains exact thickness and flatness.

Smoother Surface: No scale or roughness, reducing the need for secondary finishing.

Better Edge Quality: Clean, burr-free edges improve safety and fitment.

Enhanced Strength: Work hardening increases mechanical performance.

Improved Machinability: Easier to cut, drill, and form with minimal tool wear.

For applications where appearance, fit, and performance are critical, cold rolled flat plate is the superior choice.

Sustainability and Recyclability

Steel is one of the most recycled materials in the world, and cold rolled flat plate is no exception. Made primarily from iron ore and recycled scrap, it supports sustainable manufacturing practices. Most cold rolled steel contains 30–100% recycled content and can be fully recycled at the end of its life without loss of quality.

Additionally, the cold rolling process is energy-efficient compared to hot rolling, as it doesn’t require reheating the metal. Many manufacturers are also adopting eco-friendly lubricants and closed-loop water systems to minimize environmental impact.

Handling and Storage Tips

To maintain the quality of cold rolled flat plate:

Store in a dry, climate-controlled environment to prevent rust.

Keep oiled or coated surfaces intact until ready for use.

Use protective spacers when stacking to avoid surface scratches.

Handle with clean gloves to prevent fingerprint corrosion.

Proper storage ensures the material remains in optimal condition for fabrication.

The Future of Cold Rolled Flat Plate

As manufacturing becomes more automated and precision-driven, demand for cold rolled flat plate continues to grow. Emerging trends include:

Ultra-High-Strength Low-Alloy (HSLA) Cold Rolled Steels for lightweight automotive parts.

Digital Quality Monitoring using AI and sensors to ensure consistency.

Thinner, Stronger Gauges for miniaturized electronics and drones.

Integration with Smart Factories for seamless CNC and robotic processing.

These advancements ensure that cold rolled flat plate will remain a cornerstone of modern industrial production.

Conclusion

Cold rolled flat plate is more than just a sheet of steel—it’s a high-precision engineering material that enables innovation, efficiency, and reliability across countless industries. From its smooth, scale-free surface to its enhanced strength and dimensional accuracy, this versatile product meets the demands of today’s most advanced manufacturing environments.

Whether you're fabricating delicate electronic enclosures or robust industrial machinery, choosing cold rolled flat plate means investing in quality, consistency, and performance. As technology evolves and industries push the boundaries of design, cold rolled steel will continue to play a vital role in building the future.

English

English русский

русский عربى

عربى 中文简体

中文简体