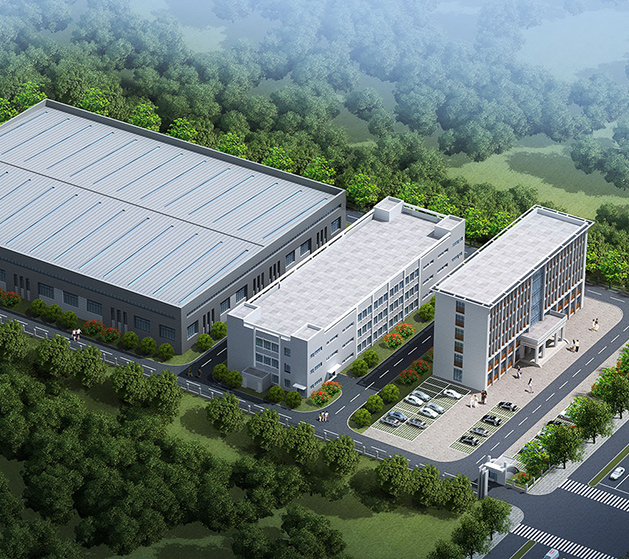

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Hot Rolled Flat Plate Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply Stainless Steel 304, 304L, 316L, 321, 2205, 2507 Hot Rolled Flat Plate wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More -

Intustry News 2025-06-11

Stainless steel coils are widely used in many industries such as construction, kitchenware, automobi...

View More

Hot Rolled Flat Plate Industry knowledge

Wuxi Chengfeng Metal Technology Co., Ltd.: The Versatility of Hot-Rolled Flat Plates

Wuxi Chengfeng Metal Technology Co., Ltd. is a leading enterprise in the metal industry, specializing in the production and trade of high-quality stainless steel and nickel-based alloy raw materials. Among our flagship products, hot-rolled flat plates stand out for their exceptional performance, uniformity, and versatility.

Superior Surface Quality and Dimensional Accuracy Hot-rolled flat plates are produced directly from steel billets through a process of continuous casting and rolling. This method ensures a smooth and flat surface, characterized by excellent surface quality and high dimensional accuracy. The uniformity in thickness and smoothness makes these plates suitable for applications where surface quality is paramount.

High Strength and Toughness One of the key attributes of hot-rolled flat plates is their impressive strength and toughness. These plates can withstand substantial loads and pressures, making them ideal for heavy-duty applications. The manufacturing process imparts mechanical properties that ensure durability and reliability in various operating conditions.

Excellent Uniformity and Stability The hot rolling, pickling, and flattening processes contribute to the uniformity and stability of both the surface and internal structure of the plates. This characteristic is vital in maintaining performance standards across different applications, ensuring that the plates do not experience unexpected failures during use.

Standard Sizes for Versatility Our hot-rolled flat plates are available in standard sizes of 15006000 mm, 18006000 mm, and 2000*6000 mm. This range of dimensions allows us to cater to various client needs, facilitating efficient usage in diverse projects.

The production of hot-rolled flat plates at Wuxi Chengfeng Metal Technology Co., Ltd. involves several key steps that ensure quality and precision:

Hot Rolling The process begins with heating steel billets, which are then passed through rollers to achieve the desired thickness. This initial step is crucial for shaping the plates and imparting strength.

Pickling After hot rolling, the plates undergo pickling to remove surface impurities, such as scale and oxidation. This step enhances the surface quality and prepares the plates for subsequent processes.

Flattening The plates are flattened to achieve uniform thickness and smoothness, which are essential for maintaining quality across the board.

Shearing and Longitudinal Shearing Once flattened, the plates are sheared to specific lengths as required by clients. Longitudinal shearing may also be employed to produce narrower strips from the wider plates, ensuring versatility in meeting diverse project requirements.

Hot-rolled flat plates from Wuxi Chengfeng Metal Technology Co., Ltd. find applications across numerous sectors, underscoring their versatility:

Construction Field Hot-rolled flat plates are integral to the construction industry, widely utilized in the fabrication of steel structures for buildings, bridges, tunnels, docks, and airports. For instance, in highway construction, these plates serve as essential components for roadbeds, bridge piers, and box culverts. The structural integrity provided by hot-rolled flat plates is crucial for ensuring the safety and durability of infrastructure projects.

Manufacturing Field In manufacturing, hot-rolled flat plates are employed in the production of a wide range of mechanical equipment. These include automobiles, trains, ships, airplanes, and pressure vessels. In the automotive sector, hot-rolled flat plates are used in the fabrication of car bodies, doors, and cargo boxes. In shipbuilding, they are essential for constructing hulls, decks, and other critical components. Additionally, in the pressure vessel industry, hot-rolled flat plates are vital for manufacturing tanks, gas containers, liquid tanks, and steam generators, all of which require materials capable of withstanding high pressures.

Petrochemical and Energy Sectors The petrochemical industry also utilizes hot-rolled flat plates for constructing various equipment that must endure harsh operational conditions. This includes refineries, storage tanks, and pipeline construction. Their ability to resist corrosion and maintain structural integrity under extreme conditions makes them ideal for these applications.

Heavy Machinery and Equipment Hot-rolled flat plates are commonly used in the manufacturing of heavy machinery and equipment, where their strength and durability are critical. They provide the necessary support and structure for various industrial applications, ensuring that machinery operates efficiently and safely.

Wuxi Chengfeng Metal Technology Co., Ltd. is committed to delivering high-quality hot-rolled flat plates that meet the rigorous demands of various industries. With a robust production process and a focus on quality, we ensure that our products provide exceptional performance, reliability, and versatility. Our hot-rolled flat plates are integral to numerous applications, from construction and manufacturing to petrochemical and energy sectors, reinforcing our position as a trusted leader in the metal technology industry. Whether serving domestic or international clients, our dedication to excellence ensures that we continue to meet and exceed industry standards.

English

English русский

русский عربى

عربى 中文简体

中文简体