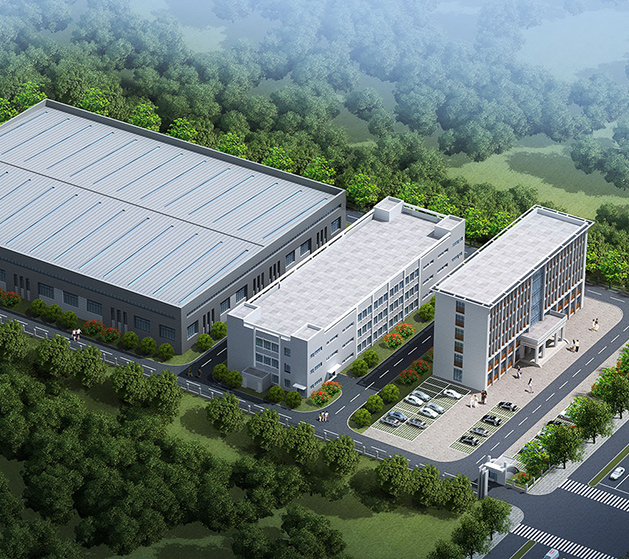

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Cold Rolled Flat Plate Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply Stainless Steel 201, 304, 304L, 316, 316L, 321 Cold Rolled Flat Plate wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-10

304 vs. 316 Stainless Steel Coils: Key Differences and ApplicationsIntroductionStainless steel coils...

View More -

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More

Cold Rolled Flat Plate Industry knowledge

The characteristics and uses of Wuxi Chengfeng Metal Technology Co., Ltd.'s Cold Rolled Flat Plate

Wuxi Chengfeng Metal Technology Co., Ltd. offers high-quality cold-rolled flat plates known for their high strength, excellent processing performance, and superior surface quality. The company's cold-rolled flat plates are made using advanced cold rolling techniques, which ensure dimensional precision and uniform surface finish. Below are the detailed characteristics and applications of Wuxi Chengfeng's cold-rolled flat plates:

Enhanced strength is achieved through the cold rolling process, which reduces the grain boundary size in the steel, making the plates stronger and more durable.

This property makes them suitable for applications that require robust and durable materials, especially in structural and engineering projects.

The cold-rolled flat plates have good toughness, meaning they can withstand high strain and mechanical stress without breaking.

This characteristic is especially important in applications where resilience to impact and stress is needed.

The plates exhibit high dimensional accuracy and a smooth, flat surface, making them easy to process, cut, and shape.

They can be formed into various shapes, including plates, rods, wires, and tubes, allowing for versatile use in different manufacturing and industrial applications.

After surface passivation, the cold-rolled flat plates achieve enhanced corrosion resistance against atmospheric, water, and acidic environments.

This feature helps extend the lifespan of the plates in corrosive environments, making them ideal for outdoor and marine applications.

The cold-rolling process ensures a smooth, uniform surface finish, which is crucial for applications requiring a high-quality appearance.

It also facilitates coating, painting, and other surface treatments.

Cold-rolled flat plates are commonly used in the manufacture of automotive components, such as body panels, chassis parts, and structural elements, where high strength, toughness, and dimensional precision are crucial.

The smooth surface allows for efficient painting and coating processes, which are essential for vehicle aesthetics and corrosion protection.

Used in the production of household appliances such as refrigerators, washing machines, ovens, and microwave casings, where high-quality surface finish and good processing performance are needed.

The cold-rolled flat plates' corrosion resistance ensures that the appliances remain durable and functional over time.

In construction, these plates are used in the fabrication of building structures, frameworks, roofing panels, and architectural components, where strength and durability are important.

Their high toughness and dimensional accuracy make them suitable for structural applications that demand reliable and stable materials.

The cold-rolled flat plates are employed in the production of electronic enclosures, casings, and hardware components where high precision and excellent surface quality are required.

The good processing performance allows for intricate shaping and fabrication.

Cold-rolled flat plates are utilized in the production of machinery parts and equipment, including industrial machinery, tools, and machine frames.

Their high strength makes them suitable for heavy-duty components, while the flat, smooth surface facilitates further machining and finishing.

Due to the high-quality surface finish, the plates are used in decorative applications such as architectural facades, interior panels, and furniture design.

The ability to maintain a polished or coated finish makes them ideal for aesthetic applications.

Wuxi Chengfeng uses advanced cold rolling technology to ensure tight dimensional tolerances and high-quality surface finish, meeting the stringent requirements of various industries.

Customizable Options: The company offers custom sizes and surface treatments to meet specific customer needs, providing a tailored approach for different applications.

Wuxi Chengfeng is committed to rigorous quality control standards, ensuring that every batch of cold-rolled flat plates is consistent in quality and performance.

The durability and processing efficiency of these plates result in longer service life and lower maintenance costs, offering a cost-effective solution for end-users.

1000x2000 mm, 1219x2438 mm, 1500x3000 mm. Custom sizes can also be provided upon request.

Thickness Range: Available in various thicknesses to suit different industrial applications.

Wuxi Chengfeng Metal Technology Co., Ltd.'s cold-rolled flat plates offer a combination of high strength, toughness, and excellent processing capabilities, making them suitable for a wide range of industrial, automotive, construction, and decorative applications. Their superior corrosion resistance and high-quality surface finish ensure long-lasting performance, while the availability of standard and custom sizes provides flexibility to meet diverse project requirements.

English

English русский

русский عربى

عربى 中文简体

中文简体