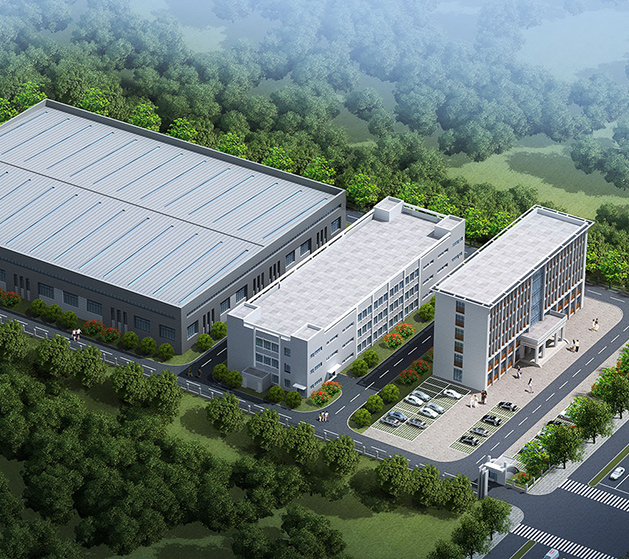

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Stainless Steel Seamless Pipe Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply 201, 304, 304L, 316L, 321, 310S, 2205, 2507 Stainless Steel Seamless Pipe wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More -

Intustry News 2025-06-11

Stainless steel coils are widely used in many industries such as construction, kitchenware, automobi...

View More

Stainless Steel Seamless Pipe Industry knowledge

Understanding the Differences in Stainless Steel Seamless Pipes

At Wuxi Chengfeng Metal Technology Co., Ltd., we take pride in producing high-quality stainless steel seamless pipes that meet the diverse needs of various industries. Our seamless pipes are manufactured through specific processes, each yielding distinct characteristics suitable for different applications.

The manufacturing of stainless steel seamless pipes generally involves two main processes: hot rolling and cold drawing. Each of these processes has its unique attributes that influence the final product’s properties.

In this initial stage, raw stainless steel materials, such as 304, 316L, or 321 grades, are heated to a specific temperature. This heating makes the metal malleable, allowing it to be shaped into the desired form through the rolling mill.

After the hot rolling process, a layer of oxide scale forms on the pipe's surface due to high temperatures. This scale must be removed through pickling, which cleans the pipe of impurities like rust and oxide.

Hot-rolled pipes exhibit a rough surface finish and higher levels of residual stress due to the rapid cooling that occurs after rolling. However, they generally possess excellent toughness and are suitable for applications where the mechanical properties are paramount.

Cold Drawing

Following the hot rolling process, the rough pipes undergo cold drawing. This process involves pulling the pipes through a die to achieve the desired diameter and wall thickness.

After cold drawing, the pipes typically undergo heat treatment, which enhances their mechanical properties and improves corrosion resistance.Cold-drawn pipes are often polished to achieve a smooth surface finish, making them ideal for applications requiring aesthetic appeal and cleanliness.Cold-drawn pipes exhibit superior dimensional accuracy and improved surface quality compared to hot-rolled pipes. They also have higher strength due to work hardening that occurs during the drawing process.

Classification of Stainless Steel Seamless Pipes

At Wuxi Chengfeng, we classify our stainless steel seamless pipes based on their intended applications:

Made primarily for the pharmaceutical, food processing, and chemical industries, sanitary pipes are lightweight and corrosion-resistant. They are often produced using cold-drawn processes to ensure a high level of cleanliness and surface smoothness.

These pipes are designed for transporting fluids such as water, oil, and gas. Both hot-rolled and cold-drawn processes can be utilized depending on the required specifications. Hot-rolled fluid pipes may be more economical, while cold-drawn versions offer better precision and surface finish.

Seamless heat exchange tubes are crucial in boiler and power generation applications. They require high strength and resistance to heat and corrosion. Both manufacturing processes can be employed, but cold drawing is often preferred to achieve the precise dimensions and mechanical properties necessary for high-pressure environments.

Features of Stainless Steel Seamless Pipes

The seamless pipes produced by Wuxi Chengfeng possess several standout features:

Our stainless steel seamless pipes demonstrate excellent resistance to corrosive environments, making them suitable for a wide range of industrial applications.These pipes can withstand high-temperature conditions, forming a protective oxide layer that prevents further oxidation.

The pipes exhibit good plasticity and can be easily processed through both cold and hot methods, allowing for versatility in manufacturing.

High Strength and Toughness

With high tensile strength and toughness, our stainless steel seamless pipes meet the rigorous demands of various applications, from construction to aerospace.

The applications of our stainless steel seamless pipes are vast and diverse:

They serve as efficient conduits for transporting oil, natural gas, water, and other fluids. Their hollow cross-section provides a lightweight alternative to solid steel, optimizing strength while reducing weight.

Used in machinery and equipment where durability and corrosion resistance are essential, such as in chemical processing and power generation.Our pipes are utilized in structural applications, where their strength and corrosion resistance contribute to the longevity and safety of constructions.

The aerospace sector benefits from our high-performance seamless pipes for various applications, including fuel lines and hydraulic systems. Similarly, in the automotive industry, they are used for exhaust systems and structural components.

Food and Pharmaceutical Industries

Sanitary pipes produced through cold drawing are crucial for maintaining hygiene and safety standards in food processing and pharmaceutical applications.

English

English русский

русский عربى

عربى 中文简体

中文简体