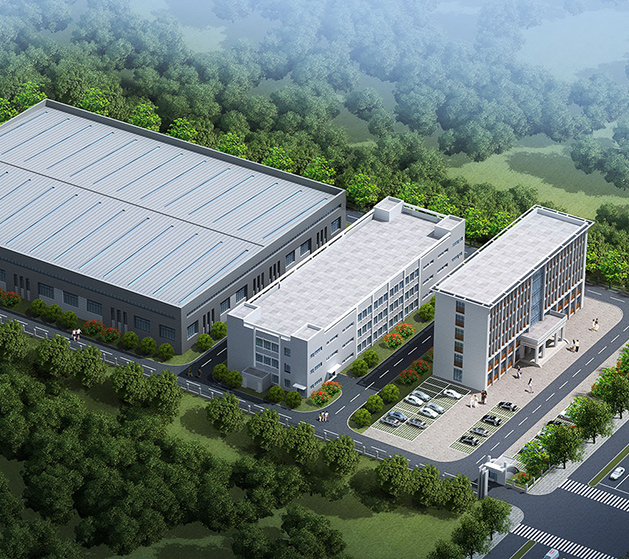

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Stainless Steel Flange Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply 201, 304, 304L, 316L, 321, 310S, 347 Stainless Steel Flange wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More -

Intustry News 2025-06-11

Stainless steel coils are widely used in many industries such as construction, kitchenware, automobi...

View More

Stainless Steel Flange Industry knowledge

The Characteristics and Uses of Wuxi Chengfeng Metal Technology Co., Ltd.'s Stainless Steel Flanges

Wuxi Chengfeng Metal Technology Co., Ltd. specializes in the production of high-quality stainless steel flanges designed to meet the diverse needs of various industries. Our flanges are renowned for their durability, versatility, and excellent performance, making them a reliable choice for applications that require secure and efficient piping connections.

Stainless steel is known for its remarkable resistance to corrosion, particularly in harsh environments. Our flanges, made from materials such as 201, 304, 304L, 316L, 321, 310S, and 347, can withstand exposure to moisture, chemicals, and high temperatures, ensuring longevity and reliability in various applications.

The mechanical strength of stainless steel ensures that our flanges can endure high pressures and extreme conditions. This durability makes them suitable for critical applications in industries where safety and structural integrity are paramount.

We offer a range of surface finishes, including blank, matte, mirror, and sandblasted options. These finishes not only enhance the aesthetic appeal of the flanges but also contribute to their resistance to wear and corrosion.

Wuxi Chengfeng provides a wide selection of flange types to suit different piping needs, including flat welded flanges, butt welded flanges, socket welded flanges, threaded flanges, loose sleeve flanges, special flanges, reducer flanges, and pressure vessel flanges. This variety ensures that our customers can find the perfect solution for their specific applications.

Our flanges come in a range of sizes, including reducing flanges (DN15-DN2000), pressure vessel flanges (DN300-DN3000), and threaded flanges (DN8-DN100). This flexibility allows us to cater to the unique requirements of each project.

Many of the stainless steel grades used in our flanges are designed to withstand high temperatures, making them ideal for applications in industries like petrochemicals and power generation where temperature extremes are common.

The manufacturing process of stainless steel flanges at Wuxi Chengfeng involves several critical steps to ensure the highest quality:

We begin by selecting premium-grade stainless steel that meets specific industry standards. The choice of materials like 304, 316L, and 321 ensures excellent performance in corrosive environments.

The raw stainless steel is cut into circular discs of the required thickness. These discs are then formed into flanges using advanced machining techniques, ensuring precise dimensions and a high-quality finish.

Depending on the type of flange, various welding techniques are employed to assemble components. For instance, butt welded and socket welded flanges are formed through high-quality welding processes that guarantee strong and reliable joints.

After forming, the flanges undergo surface treatment processes to achieve the desired finish. This can include pickling, passivation, and polishing to enhance corrosion resistance and appearance.

Rigorous quality control measures are implemented throughout the manufacturing process. Each batch of flanges is tested for dimensional accuracy, surface quality, and mechanical properties to ensure compliance with international standards.

Finally, the finished flanges are carefully packaged to prevent damage during transportation. Our logistics team ensures timely delivery to meet customer needs.

Wuxi Chengfeng’s stainless steel flanges are widely used across various industries, owing to their exceptional performance characteristics:

Flanges are critical in the oil and gas sector, where they are used to connect pipelines and equipment. Their resistance to corrosion and high temperatures makes them suitable for drilling rigs, refineries, and offshore platforms.

In chemical plants, stainless steel flanges facilitate the safe transport of corrosive substances. The durability and corrosion resistance of our flanges ensure that they can withstand the harsh conditions prevalent in chemical processing environments.

Our flanges are also utilized in the food and beverage sector, where hygiene and safety are paramount. Stainless steel’s non-reactive nature makes it an ideal choice for piping systems used in food processing, brewing, and dairy production.

The pharmaceutical industry demands high standards for equipment and materials. Our stainless steel flanges meet stringent regulations, ensuring that they are suitable for use in sanitary applications where contamination is a concern.

In construction, flanges are used to connect structural components, HVAC systems, and piping networks. Their strength and reliability make them essential for safe and efficient building practices.

Stainless steel flanges are employed in marine environments due to their excellent resistance to saltwater corrosion. They are used in shipbuilding, offshore platforms, and coastal infrastructure.

In power plants, flanges connect pipes that transport steam, water, and other fluids under high pressure and temperature. Our flanges are designed to handle these demanding conditions, ensuring the safety and efficiency of power generation processes.

English

English русский

русский عربى

عربى 中文简体

中文简体