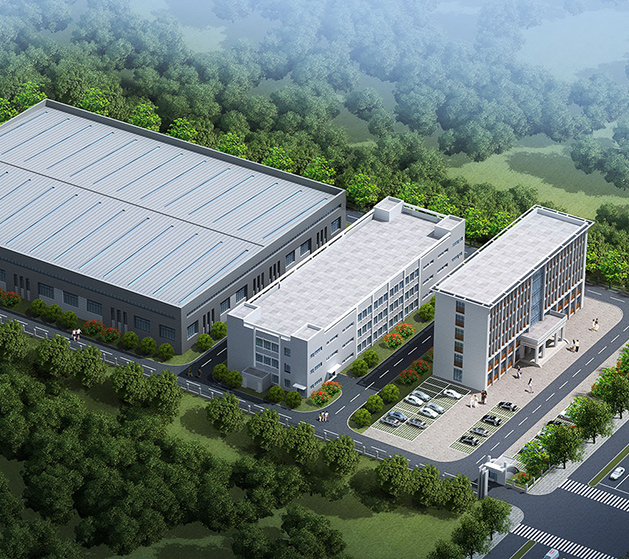

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Cold Rolled Coil Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply Stainless Steel 201, 304, 304L, 316, 316L, 321 Cold Rolled Coil wholesale.

Quick Contact

Recent News

-

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More -

Intustry News 2025-06-11

Stainless steel coils are widely used in many industries such as construction, kitchenware, automobi...

View More -

Stainless Steel Flat Steel: Why is it known as a solid support for modern industry and construction?Intustry News 2025-06-06

In the field of modern industry and construction, the performance of materials directly affects the ...

View More

Cold Rolled Coil Industry knowledge

Wuxi Chengfeng Metal Technology Co., Ltd.: The Versatility of Cold Rolled Coils

Wuxi Chengfeng Metal Technology Co., Ltd. has established itself as a leader in the manufacturing of high-quality cold rolled coils, catering to a wide array of industries. These coils are integral in various applications due to their unique properties and versatility.

The production of cold rolled coils involves a meticulously planned process that ensures quality and consistency at every stage. The key steps are:

Shearing of Mother Coils The process begins with mother coils made from hot-rolled plates. These coils are cut to the required width and length using advanced shearing machines. This initial step is crucial for ensuring that the material is appropriately sized for subsequent processing.

Degreasing and Cleaning After shearing, the coils undergo a degreasing and cleaning process to remove oil, dirt, and other impurities from their surfaces. This cleaning is essential to enhance the quality of the final product, ensuring that surface contaminants do not affect the coating or further processing.

The cleaned coils are then annealed, a heating process that improves their plasticity and surface quality. Annealing is critical for enhancing the ductility of the metal, allowing it to be shaped more easily in later stages of manufacturing.

Cold Rolling Next, the annealed coils are fed into a cold rolling mill. This step involves a series of roller pressing and stretching processes, transforming the mother coils into thin plates or strips. The cold rolling process not only reduces the thickness of the coils but also enhances their mechanical properties.

Rust Removal and Polishing Following cold rolling, the products undergo rust removal and polishing treatments. These processes improve the surface finish and glossiness of the coils, making them more appealing and suitable for various applications.

Leveling The final step involves leveling the cold-rolled coils to achieve the required thickness and flatness. This ensures that the products meet precise specifications, which is crucial for quality control in manufacturing.

Cold rolled coils produced by Wuxi Chengfeng Metal Technology Co., Ltd. boast several noteworthy features:

These coils exhibit excellent durability, making them suitable for a wide range of demanding applications. Their robust nature ensures longevity and reliability in various environments.

Cold rolled coils have a high resistance to heat, allowing them to perform well in applications where thermal stability is essential.

Heat Reflectivity With their silver-white surface finish, these coils possess good heat reflectivity, contributing to energy efficiency in various applications.

Surface Quality The surface quality of cold rolled coils is consistently high, with a smooth and attractive finish that enhances their aesthetic appeal and suitability for consumer-facing products.

Processing Performance These coils exhibit processing and spraying performance similar to galvanized steel sheets, allowing for diverse applications in manufacturing.

Welding Performance The cold rolled coils have good welding properties, making them ideal for applications that require structural integrity and strong joints.

The versatility of cold rolled coils makes them applicable in numerous industries, each requiring specific properties and performance characteristics:

Automobile Manufacturing Cold rolled coils are extensively used in the automotive sector for manufacturing components such as bodies, doors, roofs, and wheel covers. Their durability and formability make them ideal for producing parts that must withstand mechanical stresses.

Home Appliance Manufacturing The stable surface finish and quality of cold rolled coils are essential in the production of home appliances. Products such as washing machines, refrigerators, microwave ovens, and air conditioners benefit from the superior properties of these coils.

Construction Industry Cold rolled coils are crucial in constructing building structures. Their stable dimensions and smooth surfaces make them suitable for manufacturing beams, columns, and other essential components. They are also used for doors, windows, stairs, and railings.

Machinery Manufacturing In the machinery sector, cold rolled coils are utilized to produce structural parts, transmission components, and hydraulic parts. Their excellent mechanical properties and formability ensure efficient and reliable equipment manufacturing.

Electrical Products These coils are also instrumental in manufacturing electrical equipment such as motors and transformers, where high-performance materials are crucial for efficiency and safety.

Locomotives and Rolling Stock Cold rolled coils are used to manufacture structural parts and body shells for railway vehicles, ensuring safety and reliability in transportation.

Aviation The aerospace industry utilizes cold rolled coils for producing aircraft parts and engines, where precision and performance are paramount.

Food Cans These coils play a significant role in the food packaging sector, specifically in manufacturing bottom covers and side seals of food cans, ensuring food safety and longevity.

Precision Instruments Cold rolled coils are essential in producing structural components for precision instruments, where accuracy and material integrity are critical.

English

English русский

русский عربى

عربى 中文简体

中文简体