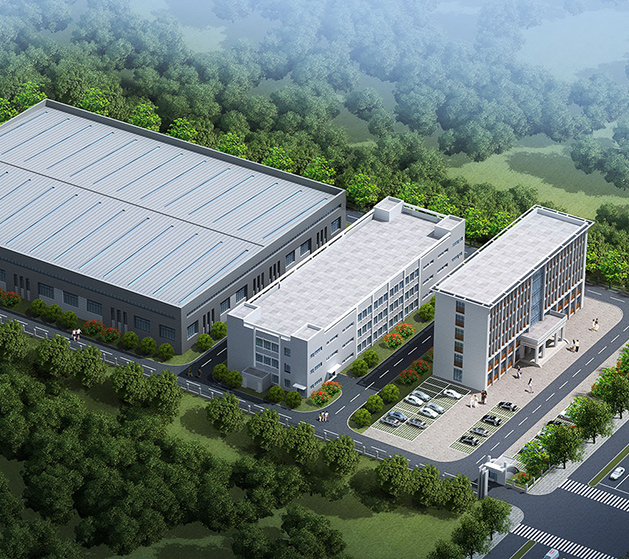

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Stainless Steel Welded Pipe Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply 201, 304, 316L, 321 Stainless Steel Welded Pipe wholesale.

Quick Contact

Recent News

-

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More -

Intustry News 2025-06-11

Stainless steel coils are widely used in many industries such as construction, kitchenware, automobi...

View More -

Stainless Steel Flat Steel: Why is it known as a solid support for modern industry and construction?Intustry News 2025-06-06

In the field of modern industry and construction, the performance of materials directly affects the ...

View More

Stainless Steel Welded Pipe Industry knowledge

The Characteristics and Uses of Stainless Steel Welded Pipe

Wuxi Chengfeng Metal Technology Co., Ltd. is committed to producing high-quality stainless steel welded pipes that cater to a wide range of industrial and decorative applications. These pipes offer a unique combination of performance characteristics, manufacturing efficiency, and versatility, making them an essential choice in various sectors.

One of the standout features of stainless steel welded pipes is their exceptional resistance to corrosion. This property is primarily attributed to the presence of chromium in the alloy, which forms a protective oxide layer on the surface. As a result, these pipes are ideal for use in environments exposed to moisture, chemicals, and corrosive substances.

Although the strength of welded pipes is generally lower than that of seamless pipes, our products are designed to meet rigorous strength requirements. They exhibit high tensile strength and can withstand considerable pressure and stress, making them suitable for demanding applications.

Stainless steel welded pipes can endure high temperatures without losing their structural integrity. This characteristic makes them suitable for applications in industries such as oil and gas, where pipes often encounter extreme temperatures.

Easy Processing and Fabrication

The welded design allows for easier fabrication compared to seamless alternatives. These pipes can be readily cut, bent, and shaped, facilitating their use in a variety of construction and manufacturing projects.

Wuxi Chengfeng offers a wide range of sizes, wall thicknesses, and surface finishes for our welded pipes. This diversity ensures that we can meet the specific requirements of different projects, whether industrial or decorative.

The production process for welded pipes is generally more economical than that for seamless pipes, resulting in lower overall costs for our customers. This cost advantage, combined with the pipes’ performance characteristics, makes them a popular choice in many applications.

The manufacturing process for stainless steel welded pipes at Wuxi Chengfeng involves several key steps:

The process begins with high-quality stainless steel coils. These coils are cut and trimmed to the desired dimensions.

The cut sheets are then fed into a plate rolling machine, where they are curled and formed into a round tube core.

The tube core is welded into a continuous pipe using advanced welding techniques. This welding process is crucial for ensuring the strength and integrity of the pipe.

After welding, the pipe undergoes cold forming to achieve the required outer diameter and wall thickness. This step enhances the pipe's mechanical properties.

The welded pipe is trimmed to the specified length and cleaned to remove any contaminants. This step is essential for ensuring a high-quality surface finish.

The pipe is then pickled to remove any oxide scale, followed by passivation to enhance corrosion resistance. This treatment process ensures that the final product maintains its durability and aesthetic appeal.

Each welded pipe undergoes rigorous testing to ensure it meets industry standards for quality and performance. Once approved, the pipes are packaged and prepared for shipment.

Wuxi Chengfeng’s stainless steel welded pipes are used in a wide variety of applications across multiple industries:

Our welded pipes are primarily used in industrial settings for the transportation of fluids and gases. They are commonly employed in sectors such as oil and gas, chemical processing, food and beverage, and water treatment. Their corrosion resistance and strength make them ideal for pipelines, tanks, and other infrastructure components.

Construction and Architecture

In construction, stainless steel welded pipes are favored for their aesthetic appeal and durability. They are widely used in architectural applications such as railings, staircases, and structural supports. The bright mirror finish of decorative pipes enhances the visual appeal of buildings and public spaces.

The automotive sector utilizes welded pipes for exhaust systems, chassis components, and structural applications. Their ability to withstand high temperatures and corrosive environments makes them suitable for automotive manufacturing.

Welded pipes are also used in furniture manufacturing, particularly for modern and industrial-style designs. Their sleek appearance and strength contribute to the durability of furniture pieces.

Stainless steel welded pipes are used in the manufacture of electrical conduits and enclosures. Their resistance to corrosion and high temperatures makes them ideal for protecting sensitive electrical components.

In the aerospace industry, stainless steel welded pipes are utilized for fuel lines and hydraulic systems, where strength and reliability are paramount.

English

English русский

русский عربى

عربى 中文简体

中文简体