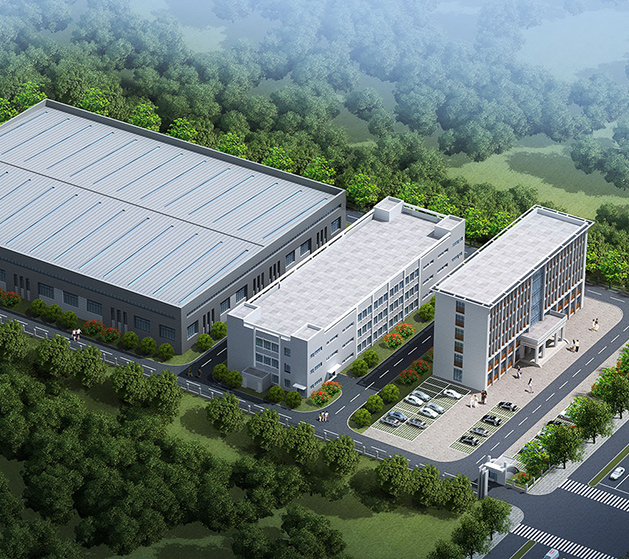

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Stainless Steel Elbow Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply 304, 304L, 316L Stainless Steel Elbow wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-10

304 vs. 316 Stainless Steel Coils: Key Differences and ApplicationsIntroductionStainless steel coils...

View More -

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More

Stainless Steel Elbow Industry knowledge

The Characteristics and Uses of Wuxi Chengfeng Metal Technology Co., Ltd.'s Stainless Steel Elbow

Wuxi Chengfeng Metal Technology Co., Ltd. is renowned for its high-quality stainless steel elbows, which are essential components in piping systems across various industries. These fittings are designed to connect pipes and alter their direction, ensuring efficient fluid transport and optimal system performance.

Our stainless steel elbows are available in various grades, primarily 304, 304L, and 316L. Each grade offers distinct properties that cater to specific applications:

This widely used stainless steel grade provides excellent corrosion resistance and is suitable for most general applications. A low-carbon variant of 304, this grade minimizes the risk of sensitization and is ideal for welding applications.Known for its superior corrosion resistance, particularly in harsh environments, 316L is commonly used in marine and chemical applications.

Wuxi Chengfeng offers a variety of surface finishes to meet diverse customer needs:

A basic finish providing standard protection against corrosion.

A non-reflective surface that offers aesthetic appeal while maintaining corrosion resistance.

This polished finish provides a bright, shiny appearance, ideal for decorative applications.

A textured finish that enhances surface adhesion for coatings and provides an industrial look.

Our stainless steel elbows are manufactured in various types to suit different connection methods and applications:

Designed for welded connections, providing a strong and permanent joint.

Created through stamping processes, these elbows are often used for lighter-duty applications.

Made from molten stainless steel, these elbows are suitable for high-stress applications.

Offering superior strength, these elbows are ideal for high-pressure systems.

Designed for easy assembly and disassembly, often used in temporary setups.

Our stainless steel elbows come in a range of sizes to accommodate various pipe diameters:

45° Elbow: Available in sizes such as 1/2"X2.5mm, 3/4"X2.5mm, and 1"X2.5mm, providing moderate directional changes.

90° Elbow: Offered in sizes like 1/2"X2.5mm, 3/4"X2.5mm, and 1"X2.5mm, ideal for sharp turns in piping systems.

18° Elbow: These elbows are available in the same size range, allowing for gentle turns in piping configurations.

The production of stainless steel elbows at Wuxi Chengfeng involves a meticulous manufacturing process that ensures high quality and reliability:

Cold bending is the primary technique used in the production of stainless steel elbows. This method avoids high-temperature exposure, reducing the risk of corrosion. The elbows are shaped using either a mandrel pipe bender or a top bending method, which allows for precise angles and smooth transitions.

After the bending process, each elbow undergoes rigorous flaw detection to identify any defects. This step is critical in ensuring the integrity of the product and its suitability for the intended application.

Before leaving the factory, the elbows are rinsed with hot water to remove any oil stains and dirt from the inner walls. This cleaning step is vital for maintaining hygiene, especially in applications involving food or pharmaceuticals.

Our elbows are subject to strict quality control measures at every stage of production. This includes dimensional checks, surface inspections, and mechanical property evaluations to ensure compliance with industry standards.

Finally, the cleaned and tested elbows are securely packaged to prevent damage during transportation. We prioritize safe and efficient shipping to deliver high-quality products to our customers.

Wuxi Chengfeng’s stainless steel elbows are utilized in a variety of industries and applications:

Stainless steel elbows are essential in oil and gas pipelines, where they facilitate directional changes and connections between different pipeline sections. Their corrosion resistance and strength ensure the reliability of these critical systems.

Chemical Processing

In chemical plants, elbows are used to connect various piping systems that handle corrosive substances. The choice of 316L grade elbows is particularly important in these environments due to their enhanced resistance to chemicals.

Our elbows are employed in water treatment facilities for connecting pipes and equipment. Their durability and resistance to rust make them ideal for applications exposed to moisture.rage processing, stainless steel elbows are critical for hygienic piping systems. Their easy cleaning and corrosion resistance make them suitable for transporting liquids and other products safely.

Elbows are commonly used in pharmaceutical applications to ensure sterile environments. The low-carbon grades, like 304L and 316L, are preferred for their corrosion resistance and suitability for welding.

In construction, stainless steel elbows are utilized in heating, ventilation, and air conditioning (HVAC) systems to connect ductwork efficiently. Their high strength and durability contribute to the overall reliability of these systems.

Due to their excellent resistance to saltwater corrosion, stainless steel elbows are widely used in marine environments, including shipbuilding and offshore structures.

English

English русский

русский عربى

عربى 中文简体

中文简体