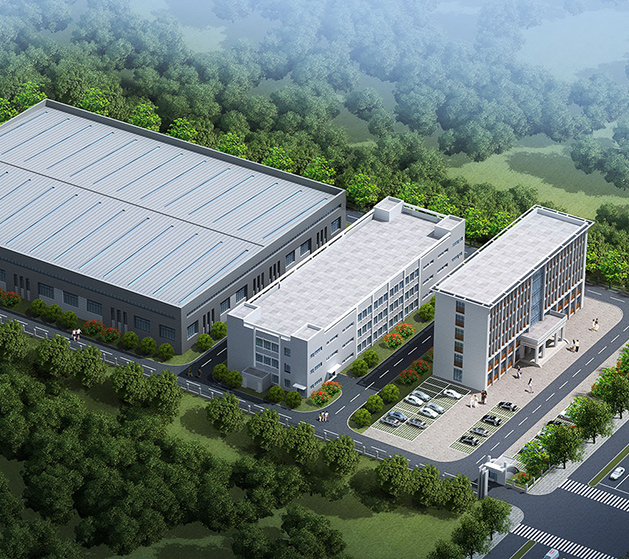

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Stainless Steel Round Steel Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply 304, 304L, 316L, 321, 2205, 2507 Stainless Steel Round Steel wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-10

304 vs. 316 Stainless Steel Coils: Key Differences and ApplicationsIntroductionStainless steel coils...

View More -

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More

Stainless Steel Round Steel Industry knowledge

What are the characteristics of Stainless Steel Round Steel with different processes?

Stainless steel round steels are integral components in numerous industries, offering durability, versatility, and aesthetic value. As a solid, long steel bar with a circular cross-section, a stainless steel round bar is utilized in a variety of applications due to its mechanical strength, corrosion resistance, and high-temperature stability. These bars come in different production types—hot-rolled, forged, and cold-drawn—each with unique characteristics that suit specific industrial needs. Wuxi Chengfeng Metal Technology Co., Ltd. provides a diverse range of stainless steel round bars with varying diameters, surface finishes, and properties to meet the requirements of different sectors. This article explores the specific characteristics of stainless steel round bars based on their production processes.

Hot-rolling is a process where the stainless steel is heated above its recrystallization temperature and then passed through rollers to achieve the desired shape. This method imparts unique qualities to the resulting round bar:

Hot-rolled stainless steels round bars often have a black, rough surface due to scale formation during the heating process. This gives them a rugged appearance suitable for structural applications where aesthetics are not a primary concern.

The hot-rolling process improves ductility and toughness, making these bars suitable for applications that require bending and shaping without fracturing. Their high strength and resistance to deformation make them ideal for heavy construction work and industrial frameworks.

Hot-rolled stainless steel round steels are produced in a wide range of diameters, from small to large (Ф1mm - Ф480mm), providing flexibility for various engineering and construction projects.The hot-rolling process is more economical compared to other production methods, making it a preferred option for large-scale projects where budget constraints exist.

Forging involves heating the stainless steel to a temperature at which it becomes malleable, and then applying mechanical force to shape it into the desired form. This process results in round bars that exhibit the following characteristics:

Forged stainless steel round bars are renowned for their superior strength and durability. The forging process refines the grain structure of the metal, leading to a more uniform and compact material that can withstand high mechanical stress.

Due to the pressing and shaping involved in forging, the round bars have fewer internal voids and a higher density. This structural integrity is crucial for applications requiring components that can endure heavy loads and intense pressures, such as in automotive and aerospace industries.

The surface of forged round bars is smoother than that of hot-rolled bars but may still require further machining or polishing for applications where a high-quality finish is essential.

Forged round bars, particularly those made from high-temperature grades like 310S, exhibit exceptional heat resistance, allowing them to be used in environments with continuous exposure to high temperatures.

Cold drawing is a process that involves drawing the stainless steel through a die without significant heating. This method produces round bars with distinct properties:

One of the standout characteristics of cold-drawn stainless steel round bars is their precise dimensional accuracy. This high level of tolerance is essential for applications where exact measurements are required, such as in the production of precision-engineered parts.

Cold-drawn round bars have a smoother, more refined surface finish compared to hot-rolled or forged bars. This makes them suitable for decorative applications, building elements like railings, and components requiring a polished look.

The cold-drawing process enhances tensile strength and yield strength due to work hardening. The result is a material that is harder and stronger than its hot-rolled counterpart. However, this may come at the expense of reduced ductility.

While cold-drawn bars are stronger, they are also more prone to cracking under excessive stress during further processing. Proper handling and machining techniques are required to avoid work hardening issues when shaping or altering the bar.

Applications Based on Processing Characteristics

Building and Architectural Use For building decorations, such as railings, handrails, and support structures, cold-drawn stain round bars are often preferred due to their smooth surface and precise dimensions. These characteristics enhance both the structural integrity and visual appeal of finished products.

Mechanical Manufacturing Forged stainless steel round bars are commonly used in mechanical manufacturing to produce machine parts that demand high strength and impact resistance, such as shafts, gears, and bolts. The forging process ensures that these parts can endure heavy mechanical loads.

High-Temperature and Corrosive Environments Hot-rolled and forged stainless steel round bars, especially those made from grades like 310S and 316L, are suitable for use in high-temperature and corrosive environments, such as chemical plants and marine applications. Their ability to resist oxidation and maintain stability under extreme conditions is invaluable.

Food and Medical Equipment Cold-drawn stainless steel round bars are used in the production of food-grade and medical equipment, where smooth surfaces and precise dimensions are critical. The bars’ resistance to corrosion ensures that they can be used in environments that require stringent hygiene standards.

English

English русский

русский عربى

عربى 中文简体

中文简体