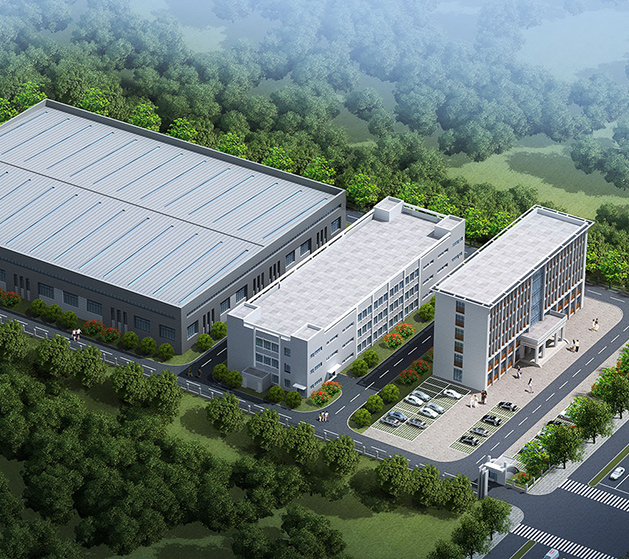

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Hastelloy Alloy Coil Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply C-276, C-22, B-2, B-3, G-3, G-20 Hastelloy Alloy Coil wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-10

304 vs. 316 Stainless Steel Coils: Key Differences and ApplicationsIntroductionStainless steel coils...

View More -

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More

Hastelloy Alloy Coil Industry knowledge

Hardness and Applications of Hastelloy Alloy Coils by Wuxi Chengfeng Metal Technology Co., Ltd.

Hastelloy alloys are a class of high-performance, corrosion-resistant materials that are widely used in industries requiring superior durability and reliability under extreme conditions. Wuxi Chengfeng Metal Technology Co., Ltd. offers a range of Hastelloy alloy coils designed for use in highly demanding environments. These coils are known for their exceptional strength, corrosion resistance, and high-temperature performance. Wuxi Chengfeng's Hastelloy alloy coils are available in a variety of sizes, from thin sheets (1.0-3.0mm) to thicker plates (4.0-15.0mm), catering to a wide range of industrial applications. The alloys are particularly suitable for environments where other materials might fail, such as in corrosive, high-temperature, and high-pressure settings.

The hardness of Hastelloy alloy coils is one of the key factors that determine their performance in various applications. Hastelloy alloys, which are primarily composed of nickel, molybdenum, and chromium, are engineered to offer excellent mechanical properties, including high hardness and tensile strength. The hardness of Hastelloy alloy coils typically ranges between 80 HRB (Rockwell B scale) to 95 HRB, depending on the specific grade of Hastelloy and the heat treatment process used.

The high hardness of Hastelloy alloy coils ensures that they can withstand wear and abrasion in addition to providing structural integrity in environments exposed to high mechanical stress. This makes Hastelloy alloy coils suitable for applications that require high performance under heavy loads and extreme conditions. Furthermore, the hardness is maintained even at elevated temperatures, ensuring long-lasting reliability in high-heat applications.

One of the standout features of Hastelloy alloy coils is their excellent corrosion resistance. These coils can perform stably over long periods in highly corrosive environments, resisting degradation caused by a variety of chemical media, including wet chlorine, oxidizing chlorides, chloride salt solutions, sulfuric acid, and oxidizing salts. Their exceptional resistance to hydrochloric acid—especially at low and medium temperatures—makes them particularly useful in industries dealing with harsh chemicals, such as chemical processing, petrochemical, and environmental protection industries.

The alloy's high strength is another important characteristic, making it ideal for use in applications that require resistance to high pressures and temperatures. The high tensile strength and hardness of Hastelloy ensure that it can maintain its structural integrity even under extreme mechanical loads. This property is critical for components that must withstand high-stress environments, such as valves, pumps, and heat exchangers in the oil and gas, aerospace, and energy industries.

Hastelloy alloy coils are known for their excellent machinability and weldability. Unlike many other high-strength materials, Hastelloy can be easily processed into complex shapes and welded without the risk of cracking. This makes it a versatile material for manufacturing components that require precise fabrication. The alloy’s ease of welding is particularly beneficial for industries where custom parts and structures need to be made with high accuracy.

Hastelloy alloy coils from Wuxi Chengfeng Metal Technology Co., Ltd. have a broad range of applications across many industries. Below are some key sectors where these high-performance materials are utilized:

Hastelloy alloy coils are used in the automobile industry to manufacture high-strength components such as engine crankshafts, camshafts, and transmission shafts. These parts need to withstand high mechanical stress and provide durability over long periods, and Hastelloy’s strength and corrosion resistance make it an ideal material for such applications. The ability of Hastelloy to maintain its mechanical properties under high pressure and temperature makes it suitable for the automotive industry's demanding performance requirements.

In the aerospace industry, Hastelloy alloys are used to produce critical components that are exposed to extreme conditions, such as blades, bearings, and gears in aircraft engines. These parts need to perform under high temperatures, high pressures, and high-speed operations. Hastelloy’s ability to resist both thermal and mechanical stress, while maintaining high strength and hardness, makes it an excellent material for aerospace applications where performance and safety are paramount.

The machinery industry relies heavily on materials that can withstand high mechanical loads and provide long-term reliability. Hastelloy alloy coils are used to manufacture high-load mechanical parts such as lifting machinery, excavators, and forging presses. The alloy’s high fatigue resistance and impact resistance ensure that the components remain functional and structurally sound even under harsh operational conditions.

The oil and gas industry often deals with harsh environments where equipment is exposed to high temperatures, high pressures, and corrosive substances. Hastelloy alloy coils are used to make components like pipelines, valves, and pressure vessels. These components need to remain functional over long periods despite exposure to corrosive substances such as sulfur compounds and brine, making Hastelloy the material of choice for these applications. The alloy’s corrosion resistance also ensures minimal maintenance and reduced downtime in oil and gas operations.

Hastelloy is widely used in the energy industry for components such as those found in nuclear power plants, thermal power plants, and geothermal plants. The alloy’s ability to withstand high temperatures, high pressure, and radiation makes it suitable for critical components in nuclear reactors and other high-performance systems. Hastelloy alloys are also used in heat exchangers and turbines, where durability and high strength are crucial for long-term operation.

Hastelloy’s high-temperature performance also makes it an ideal material for the metallurgical industry. Components used in high-temperature processes such as blast furnaces, mining equipment, and metallurgical reactors must resist extreme temperatures and pressures. Hastelloy alloy coils are used to make these critical components, where they provide long-term durability and resistance to thermal degradation.

English

English русский

русский عربى

عربى 中文简体

中文简体