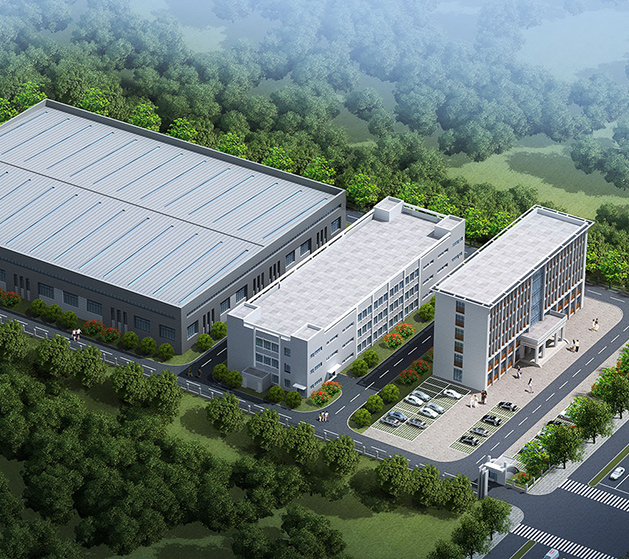

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Fixed Rolled Medium And Thick Plate Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply Stainless Steel 304, 304L, 316L, 321, 2205, 2507, 347, 904L Fixed Rolled Medium And Thick Plate wholesale.

Quick Contact

Recent News

-

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More -

Intustry News 2025-06-11

Stainless steel coils are widely used in many industries such as construction, kitchenware, automobi...

View More -

Stainless Steel Flat Steel: Why is it known as a solid support for modern industry and construction?Intustry News 2025-06-06

In the field of modern industry and construction, the performance of materials directly affects the ...

View More

Fixed Rolled Medium And Thick Plate Industry knowledge

Wuxi Chengfeng Metal Technology Co., Ltd.: The Excellence of Fixed Rolled Medium and Thick Plates

Wuxi Chengfeng Metal Technology Co., Ltd. stands as a prominent player in the metal manufacturing industry, specializing in a diverse range of steel products, including fixed rolled medium and thick plates. Known for their reliability and strength, these plates are crucial components in various industrial applications.

The production of fixed rolled medium and thick plates follows a comprehensive process flow designed to ensure high quality and stable mechanical properties. The main steps involved in this process are:

Raw Materials The process begins with the selection of high-quality raw materials, which are essential for producing plates with optimal properties. The choice of materials significantly impacts the final product's performance.

Heating The raw materials are subjected to heating, which prepares them for the subsequent rolling processes. This step is crucial for enhancing the malleability of the steel, allowing for effective shaping during rolling.

Dephosphorization Following heating, a high-pressure water dephosphorization process is employed. This step is vital for removing phosphorus, which can adversely affect the steel's quality. Ensuring a low phosphorus content contributes to the smooth surface finish and overall strength of the plates.

The heated and treated materials undergo rough rolling, where they are initially shaped into plates. This stage sets the foundation for further refinement in the manufacturing process.

The finishing rolling process is critical for achieving the desired dimensions and surface quality. During this stage, the plates are rolled to their final thickness, which typically ranges from 8mm to 50mm. The precise control of thickness is essential for meeting the specific requirements of various applications.

Final Inspection and Quality Control After finishing, the plates undergo a stringent inspection process to ensure they meet the highest quality standards. This includes checking for dimensional accuracy, surface smoothness, and mechanical properties.

This multi-step production process ensures that fixed rolled medium and thick plates exhibit consistent quality and performance, making them suitable for demanding applications.

Smooth Surface Thanks to the high-pressure water dephosphorization process, our fixed rolled plates boast a smooth surface finish. This characteristic not only enhances the aesthetic appeal but also improves their performance in applications where surface quality is critical.

Verticality of Both Sides The finishing rolling process ensures that both sides of the plates maintain excellent verticality. This feature guarantees that the corners are well-defined, and the edge surface quality is high. Proper verticality is essential for ensuring accurate fit and performance in assembled products.

Accurate Scale Utilizing continuous rolling and automatic loop control techniques, we achieve high dimensional accuracy in our plates. This process minimizes issues such as steel piling or pulling, resulting in precise tolerances. Parameters such as three-point difference, same-line difference, and plate straightness exceed industry standards, ensuring reliability in various applications.

Fixed rolled medium and thick plates are versatile products that find application across a broad spectrum of industries due to their unique characteristics:

Heavy Machinery Manufacturing The strength and durability of medium and thick plates make them ideal for heavy machinery applications. They are used in the construction of components that must withstand significant loads and stresses, ensuring operational efficiency and safety.

Vehicle Manufacturing In the automotive and transportation sectors, fixed rolled plates are used in the manufacturing of various vehicle parts. Their ability to endure high pressures and loads is crucial for the performance and safety of vehicles.

Shipbuilding The shipbuilding industry relies heavily on fixed rolled medium and thick plates for constructing hulls, decks, and other vital components. The specific thickness range and mechanical properties of these plates make them suitable for marine applications, where strength and durability are paramount.

Building Components In construction, these plates serve as critical components for structural frameworks, beams, and supports. Their reliable performance ensures the integrity and safety of buildings and other structures.

Manufacture of Large-Diameter Welded Pipes Fixed rolled medium and thick plates are commonly used in producing large-diameter welded pipes, essential in various industries such as oil and gas, water supply, and sewage systems. Their robust characteristics ensure that the pipes can handle high pressures and harsh environments.

Boilers and Pressure Vessels The ability to withstand extreme conditions makes these plates suitable for manufacturing boilers and pressure vessels. Their resistance to deformation under high pressure is essential for maintaining safety and efficiency in these applications.

Military Industry The military sector requires materials that can perform under severe conditions. Fixed rolled medium and thick plates meet these demands, being used in the production of armored vehicles and other military equipment.

English

English русский

русский عربى

عربى 中文简体

中文简体