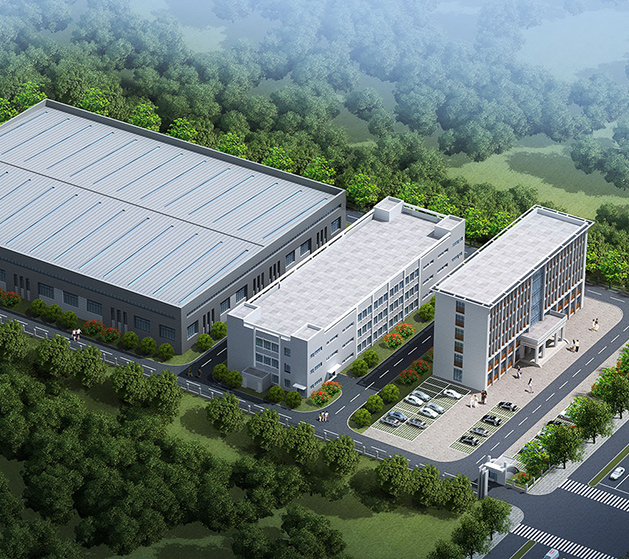

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Hastelloy Alloy Sheet Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply C-276, C-22, B-2, B-3, G-3, G-20 Hastelloy Alloy Sheet wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-10

304 vs. 316 Stainless Steel Coils: Key Differences and ApplicationsIntroductionStainless steel coils...

View More -

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More

Hastelloy Alloy Sheet Industry knowledge

Hardness and Applications of Hastelloy Alloy Sheets by Wuxi Chengfeng Metal Technology Co., Ltd.

Hastelloy a trademarked brand of high-performance alloys, is renowned for its exceptional corrosion resistance, high-temperature stability, and mechanical strength. Wuxi Chengfeng Metal Technology Co., Ltd., a leader in the trade and sale of stainless steel and nickel-based alloys, offers Hastelloy plates and sheets as part of its portfolio of advanced materials. These alloy sheets are particularly sought after for their outstanding properties in challenging industrial environments where other materials might fail.

Hastelloy alloys, including those provided by Wuxi Chengfeng Metal Technology Co., Ltd., are typically composed of a combination of nickel, molybdenum, chromium, and other elements that impart them with remarkable durability. The hardness of Hastelloy sheets is primarily determined by their specific alloy composition and treatment processes.

The typical hardness of Hastelloy alloys is measured in terms of Rockwell B (HRB) or Rockwell C (HRC) scales, with values generally ranging from 80 HRB to 95 HRB. This relatively high hardness makes Hastelloy alloy sheets suitable for demanding applications where both mechanical wear and corrosion are significant concerns. The exact hardness can vary depending on the type of Hastelloy, as the alloy's composition and heat treatment methods are tailored to optimize specific properties. For instance, Hastelloy C-276, a commonly used grade, has a hardness of around 90 HRB in its annealed state.

One of the most defining features of Hastelloy is its exceptional resistance to corrosion. Hastelloy alloys are highly resistant to a wide range of corrosive environments, including both acidic and alkaline solutions, as well as saltwater. This makes them an ideal material for industries where exposure to aggressive chemicals and harsh environments is common, such as chemical processing, power generation, and marine applications.

For instance, Hastelloy sheets can withstand oxidation, sulfidation, chlorination, and even fluorination—types of chemical attacks that would degrade other materials. The ability to resist pitting, crevice corrosion, and stress corrosion cracking further enhances the usability of Hastelloy sheets in various industrial settings.

In addition to its excellent corrosion resistance, Hastelloy also boasts outstanding high-temperature performance. The alloy retains its strength and stability even at elevated temperatures, which is critical for applications in industries such as aerospace, petrochemicals, and power plants. Hastelloy plates are capable of withstanding prolonged exposure to high temperatures without significant loss of structural integrity, making them perfect for use in heat exchangers, combustion chambers, and turbine components.

Hastelloy's high-temperature performance is characterized by its ability to resist thermal creep, which is the tendency of a material to deform slowly when subjected to high heat and pressure. This makes Hastelloy a preferred choice for high-performance applications where other metals would degrade under similar conditions.

The mechanical properties of Hastelloy alloy sheets are another important aspect that contributes to their wide-ranging industrial applications. These alloys are known for their high hardness and strength, making them capable of withstanding significant wear and tear in high-pressure environments. Hastelloy’s wear resistance also helps prevent surface damage due to abrasion, making it suitable for use in applications that involve high friction and mechanical stress, such as pumps, valves, and heat exchangers.

Hastelloy’s resistance to pitting and crevice corrosion further enhances its mechanical performance in challenging environments. This means that Hastelloy sheets are not only durable but also able to maintain their integrity in highly corrosive environments where other materials might fail due to localized corrosion or stress cracking.

Hastelloy alloys are also known for their excellent weldability. They can be connected using a variety of welding techniques, including TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and electron beam welding. The welding process does not significantly affect the overall integrity of the material, making Hastelloy a preferred choice for complex structures and components that require precise fabrication.

For industries that demand customized products or specific dimensions, Hastelloy alloy sheets can be easily fabricated into various shapes and sizes, which is crucial for the production of bespoke equipment or parts.

Hastelloy is not only a high-performance material but also an environmentally friendly choice for industries concerned with sustainability. The production and use of Hastelloy sheets do not produce harmful substances, and the material is fully compliant with environmental standards. In industries that are focused on reducing their environmental footprint, such as the energy and chemical sectors, Hastelloy is a material of choice due to its safe and green production processes.

Given its exceptional properties, Hastelloy alloy sheets are used in a wide range of industries and applications where performance under extreme conditions is crucial. Some of the primary uses of Hastelloy alloy sheets include:

Hastelloy’s corrosion resistance makes it ideal for equipment used in chemical reactors, scrubbers, and other systems that process aggressive chemicals.The high-temperature strength and durability of Hastelloy make it suitable for aerospace components, including turbine blades and exhaust systems.Hastelloy is often used in gas turbines, heat exchangers, and power plant systems, where it helps to increase the longevity and efficiency of the equipment.

Due to its resistance to seawater corrosion, Hastelloy is frequently used in components exposed to marine environments, such as ship propulsion systems, offshore drilling platforms, and desalination plants.

Hastelloy is widely used in the oil and gas industry for equipment that must operate under high pressure and temperature, such as pressure vessels, valves, and pipelines.Hastelloy’s corrosion resistance and ease of cleaning make it an ideal material for pharmaceutical equipment, including mixing tanks, reactors, and piping systems.

English

English русский

русский عربى

عربى 中文简体

中文简体