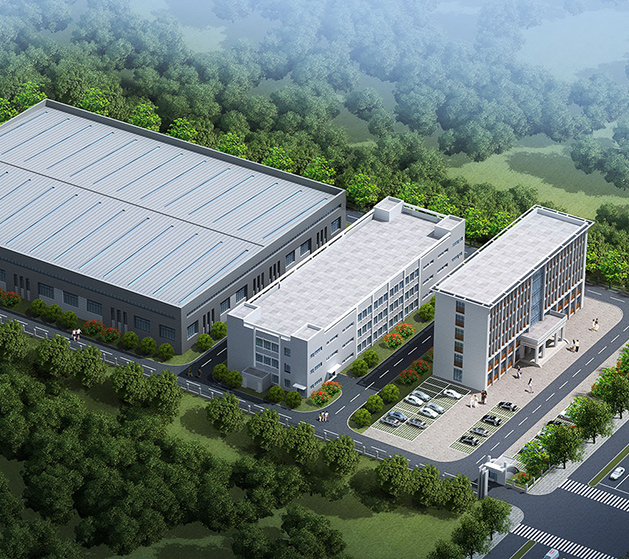

Wuxi Chengfeng Metal Technology Co., Ltd.

A company integrating design, R&D, manufacturing, sales and service.

Q. How long will it take to get a reply after we send you an inquiry?

On working days, we will reply to you within 12 hours of receiving the inquiry.Q. Are you a direct manufacturer or a trading company?

We are a factory. As Stainless Steel Angle Manufacturers, we produce and sell by ourselves.Q. What products can you provide?

We focus on the trade and sales of stainless steel and nickel-based alloy steel raw materialsQ. How about your company's production capacity?

Our material warehouse has a huge inventory of 20,000 tons of coils, providing us with strong supply chain security. Supply 304, 316L, 321, 310S, 430 Stainless Steel Angle wholesale.

Quick Contact

Recent News

-

Intustry News 2025-07-10

304 vs. 316 Stainless Steel Coils: Key Differences and ApplicationsIntroductionStainless steel coils...

View More -

Intustry News 2025-07-04

Stainless Steel Coils as an important metal material, is widely used in many industrial fields. It n...

View More -

Intustry News 2025-06-27

Stainless Steel Profiles are playing an increasingly important role in many fields such as modern co...

View More -

Intustry News 2025-06-20

The marine environment places extremely high demands on the performance of materials. Long-term expo...

View More

Stainless Steel Angle Industry knowledge

Characteristics of Different Processes in Wuxi Chengfeng Metal Technology Co., Ltd.'s Stainless Steel Angle Steel and Their Uses

Stainless steel angle steel is an essential construction and structural material known for its strength, corrosion resistance, and sleek appearance. The different types of stainless steel angle steel, specifically equal-leg and unequal-leg angles, serve various purposes across industries due to their versatility. Wuxi Chengfeng Metal Technology Co., Ltd. specializes in the production of high-quality stainless steel angle steel through several manufacturing processes: hot rolling, laser welding, and bending. Each process brings unique characteristics and advantages, making the product suitable for specific applications.

One of the most significant advantages of stainless steel angle steel is its resistance to corrosion. This property ensures long-lasting durability, even in harsh environments such as marine and industrial settings.

Stainless steel angle steel provides high structural strength, making it suitable for applications that demand load-bearing capabilities.

Aesthetic Appeal: With its sleek and polished appearance, stainless steel angle steel is an excellent choice for architectural and decorative uses.

Both sides of the angle are of equal length, offering symmetry and balance that are well-suited for general-purpose construction.

Unequal-Leg Angle Steel: The two sides differ in length, providing flexibility for specific structural requirements where one side may need to bear more load than the other.

Manufacturing Processes of Stainless Steel Angle Steel The choice of manufacturing process affects the physical properties, cost, and applicability of stainless steel angle steel. Wuxi Chengfeng Metal Technology Co., Ltd. employs three primary manufacturing methods: hot rolling, laser welding, and bending. Below, we discuss the characteristics of each process and their implications for the end product.

(1) Hot Rolling Process Characteristics:

Traditional and Economical: The hot rolling process is one of the oldest and most established methods for producing stainless steel angle steel. It involves heating the steel to high temperatures and then rolling it to the desired shape.

High Strength: The process imparts good mechanical properties to the finished product, making it robust and reliable for heavy-duty structural applications.

Scale Formation: The high temperatures can lead to the formation of a scale layer on the surface, which might require additional surface treatment if a polished appearance is needed.

Applications: Hot-rolled stainless steel angle steel is ideal for construction projects that require sturdy, cost-effective solutions. These include building frames, support structures, and large-scale infrastructure projects where the finish is less critical but strength and durability are paramount.

(2) Laser Welding Process Characteristics:

Precision and Uniformity: Laser welding involves using laser technology to fuse two pre-cut stainless steel plates along a laser welding line. This method ensures a uniform and clean weld, producing angle steel with high strength and excellent quality.

Minimal Distortion: The controlled heat input during the laser welding process reduces the likelihood of material distortion, resulting in products with precise dimensions and tight tolerances.

Smooth Finish: The surface of laser-welded angle steel is smooth and often requires minimal post-processing to achieve a polished look.

Applications: Due to its precise construction and clean appearance, laser-welded stainless steel angle steel is suitable for high-end architectural projects, decorative elements, and structural components where both aesthetic appeal and structural integrity are important. It is often used in modern building facades, interior design features, and specialty installations.

(3) Bending Process Characteristics:

Versatility: The bending process involves taking a flat stainless steel sheet and shaping it into an angle through controlled bending. This method allows for the production of custom-sized angle steel.

Dimensional Accuracy: The bending process demands careful control of the bending angle, force, and temperature to maintain precision and meet product specifications.

Flexible Production: Bending is particularly suitable for small-batch production and custom projects that require non-standard dimensions or specific design features.

Applications: Bending is often employed when specialized or smaller quantities of stainless steel angle steel are required. Applications include custom fabrication projects, industrial machinery, and bespoke construction elements where precise dimensions and specific angles are necessary.

Comparison of Process Characteristics and Their Impact on Use Each manufacturing process has unique characteristics that influence the properties and best-use scenarios of stainless steel angle steel:

Hot Rolling vs. Laser Welding: While hot rolling is cost-effective and suitable for bulk production with high strength, laser welding offers higher precision and a superior surface finish, making it ideal for projects where appearance matters.

Bending vs. Hot Rolling: Bending allows for customization and is suitable for special-order applications, while hot rolling is better for mass-produced, standardized angle steel.

Laser Welding vs. Bending: Laser welding is preferred for high-precision, visually appealing products, whereas bending is chosen for flexibility in size and shape customization.

Wuxi Chengfeng Metal Technology Co., Ltd.'s Comprehensive Offerings Wuxi Chengfeng Metal Technology Co., Ltd. leverages advanced manufacturing techniques to meet diverse client needs. The company’s stainless steel angle steel is available in a variety of grades, including 201, 304, 316L, and more, ensuring products with optimal corrosion resistance, strength, and performance. Additionally, the company provides industrial, brushed, and polished surface finishes to cater to a wide range of aesthetic and functional requirements.

English

English русский

русский عربى

عربى 中文简体

中文简体