In modern industry and construction, stainless steel flat bar has become an indispensable material in many industries due to its unique physical properties and wide range of application scenarios. Stainless steel flat bar, as a special form of stainless steel, is widely used in the manufacture of structural components, mechanical parts, architectural decoration and many other products due to its excellent corrosion resistance, strength and processing convenience.

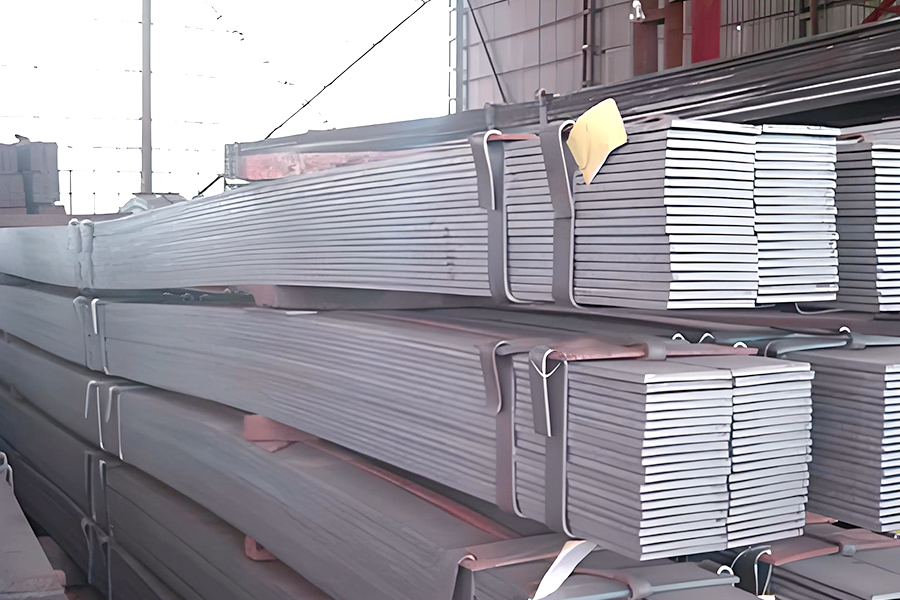

Stainless steel flat bar refers to a long strip of stainless steel material with a flat surface and uniform thickness after rolling or stretching. It usually has a rectangular, square or other regular cross-section. Depending on the different standards and requirements used, the specifications, surface treatment, strength and other properties of stainless steel flat bar can vary. It not only has the excellent characteristics of traditional stainless steel materials such as corrosion resistance and high temperature resistance, but also has a high convenience in processing and assembly due to its flat appearance and structure.

Stainless steel flat bar is generally made of stainless steel alloys (such as 304, 316, 430, etc.), and the selection of these alloys mainly depends on the environmental requirements of the specific application. For example, 304 stainless steel has good corrosion resistance in most industrial applications, while 316 stainless steel is suitable for use in more demanding environments, such as marine and chemical fields.

Strong corrosion resistance

A notable feature of stainless steel flat steel is its excellent corrosion resistance. Due to the special alloy composition of stainless steel, it can effectively prevent oxidation and resist erosion by moisture, acid, alkali and other chemicals. This makes stainless steel flat steel widely used in industries such as chemistry, food processing, and medical treatment that have high requirements for hygiene and corrosion resistance.

High strength and good toughness

Stainless steel flat steel has high strength and toughness and can withstand greater pressure and impact. It is not only suitable for structures that carry heavy loads, but also can resist the effects of various environmental changes, ensuring its long service life.

Good processability

Stainless steel flat steel has good processability and can be processed through a variety of processes such as cutting, welding, and bending. This gives it great flexibility in customization and manufacturing, and can meet the needs of different products and projects.

Aesthetics

Stainless steel flat steel has a smooth and bright surface and has a high visual effect. It is often used as a decorative material, such as in the fields of building facades and interior decoration, to enhance the overall beauty.

High temperature resistance

Stainless steel flat steel can withstand high temperatures, especially stainless steel with alloy elements such as chromium, nickel, and molybdenum, which can maintain its strength and stability in high temperature environments and is suitable for high temperature processing or heat treatment.

Stainless steel flat steel has a wide range of applications, covering almost all walks of life. The following are some typical application areas:

Construction industry

In the construction industry, stainless steel flat steel is widely used in the manufacture of building structures, decorative materials, and components such as bridges and stair railings. Due to its corrosion resistance and aesthetics, it is also often used as a material for exterior wall decoration, interior decoration elements, and door and window frames.

Machinery manufacturing

Stainless steel flat steel plays an important role in machinery manufacturing. It is often used to manufacture various mechanical parts, such as shafts, connectors, gears, etc. Due to its high strength and wear resistance, stainless steel flat steel can extend the service life of mechanical parts and reduce maintenance costs.

Food processing and medical industry

The corrosion resistance of stainless steel flat steel makes it an important material in food processing and medical equipment. In these industries, the hygiene of the material is crucial, so stainless steel flat steel is widely used in food processing equipment, medical equipment, pharmaceutical production lines and other fields.

Chemical Industry

In the chemical industry, stainless steel flat steel is used to manufacture equipment such as reactors, pipelines, and storage tanks due to its corrosion resistance and resistance to chemical erosion. It can work stably and for a long time in harsh environments such as acid and alkali corrosion.

Automotive and Transportation Industry

Stainless steel flat steel is also widely used in the automotive and transportation industries, especially in the exhaust system, body frame and parts of automobiles. The strength and durability of stainless steel enable it to improve the safety and service life of vehicles.

When choosing the right stainless steel flat steel, first determine the alloy type of the material according to the application environment. For example, 304 stainless steel is suitable for most conventional environments, while 316 stainless steel is more suitable for use in highly corrosive environments. Secondly, the size, thickness and surface treatment requirements of stainless steel flat steel need to be considered. Different applications have different requirements for these parameters, so the selection should be adjusted according to the specific situation.

With its excellent corrosion resistance, strength and aesthetics, stainless steel flat steel has shown irreplaceable advantages in many fields. Whether in construction, machinery, chemical industry or food and medical industry, stainless steel flat bar plays an important role. With the continuous advancement of industrial technology and the increasing demand, the application prospect of stainless steel flat bar will be broader and become one of the key materials supporting the development of modern industry.

English

English русский

русский عربى

عربى 中文简体

中文简体