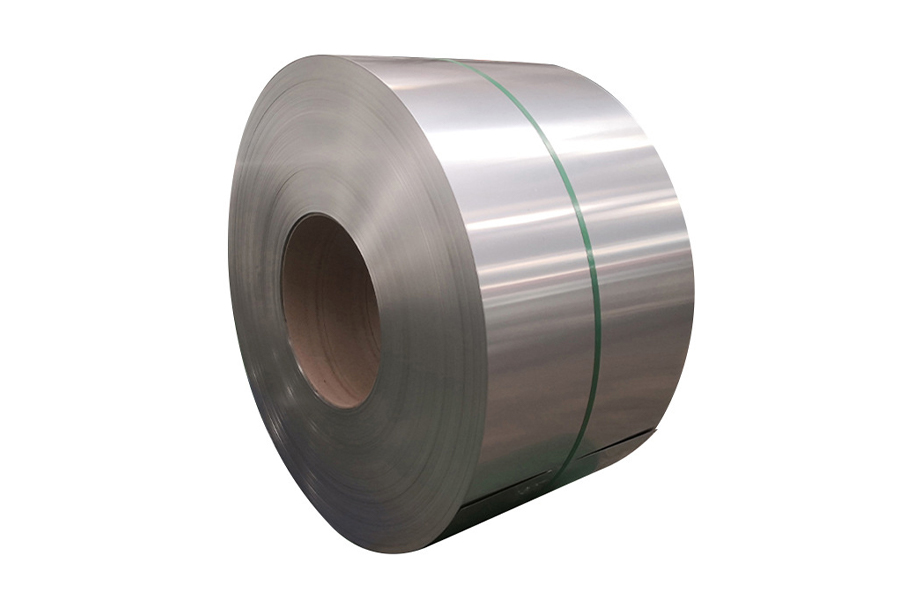

Stainless steel cold rolled coils are widely used in industries due to their precise dimensions, smooth surface finish, and superior mechanical properties. Unlike hot rolled coils, cold rolled coils undergo further processing at room temperature, which improves surface quality, hardness, and dimensional accuracy. Choosing the right coil requires a detailed understanding of its properties and how they match the intended application.

Key Grades and Their Applications

Selecting the appropriate grade is crucial for performance and longevity. Stainless steel grades vary based on chemical composition and mechanical properties.

Austenitic Grades

Austenitic stainless steels, such as 304 and 316, are known for excellent corrosion resistance, formability, and strength. These are commonly used in kitchen equipment, food processing, chemical tanks, and architectural panels.

Ferritic Grades

Ferritic grades like 430 provide good corrosion resistance and are more cost-effective than austenitic steels. They are often applied in automotive trims, appliance panels, and decorative elements.

Martensitic Grades

Martensitic stainless steels, including 410 and 420, offer higher hardness and wear resistance. These grades are ideal for cutlery, surgical instruments, and industrial components requiring durability.

Understanding Thickness and Mechanical Properties

The thickness of a cold rolled coil affects its flexibility, strength, and suitability for specific fabrication methods.

Thin Coils (0.2mm–1.0mm)

Thin coils are highly flexible and perfect for deep drawing, stamping, and decorative applications. They provide smooth surface finishes essential for visible surfaces in appliances and furniture.

Medium Thickness (1.0mm–3.0mm)

Medium-thickness coils balance strength and formability, making them suitable for automotive panels, industrial enclosures, and HVAC components.

Thick Coils (3.0mm–6.0mm)

Thicker coils offer higher structural integrity and are ideal for heavy machinery, construction supports, and industrial equipment. Machining and bending must consider the increased hardness.

Surface Finish Options and Their Importance

Cold rolled coils come in various surface finishes, which affect aesthetics, corrosion resistance, and cleaning requirements.

- BA (Bright Annealed) – Smooth, reflective, and suitable for decorative panels and appliances.

- 2B – Matte finish widely used in industrial applications and flat products requiring uniform appearance.

- HL (Hairline) – Linear brushed texture ideal for decorative facades and elevator interiors.

- Mirror Finish – Highly reflective, used for premium appliances and architectural details.

Considerations for Corrosion Resistance

Corrosion resistance is a critical factor in selecting stainless steel coils. Factors to consider include:

- Environment – Indoor vs. outdoor usage, exposure to chemicals, and humidity levels.

- Grade Selection – Austenitic grades (304, 316) offer the highest corrosion resistance.

- Protective Coatings – Passivation or thin film treatments can enhance longevity.

Fabrication Compatibility

The coil must match fabrication requirements such as bending, stamping, or welding. Key considerations include:

- Formability – Thin coils and austenitic grades excel in complex shapes.

- Weldability – Proper grade ensures minimal welding defects and durability.

- Work Hardening – Cold rolled coils harden during fabrication, so allowances must be made for post-processing.

Cost Considerations and Supply Options

Balancing performance and budget is essential. Cost factors include:

- Grade and Alloy Content – Higher nickel content increases corrosion resistance and cost.

- Thickness – Thicker coils are more expensive due to increased material usage.

- Surface Finish – Decorative finishes like mirror or HL add to manufacturing costs.

- Supplier Reliability – Ensure consistent quality and timely delivery to avoid production delays.

Summary and Selection Checklist

To choose the right stainless steel cold rolled coil, consider the following checklist:

- Identify the application and environmental conditions.

- Choose the appropriate grade for corrosion resistance and mechanical performance.

- Select the suitable thickness and surface finish.

- Verify fabrication compatibility including bending, stamping, and welding requirements.

- Compare costs, considering material, finish, and supplier reliability.

By carefully evaluating each factor, engineers, designers, and procurement specialists can ensure optimal performance, aesthetic quality, and longevity for their stainless steel cold rolled coil applications.

English

English русский

русский عربى

عربى 中文简体

中文简体