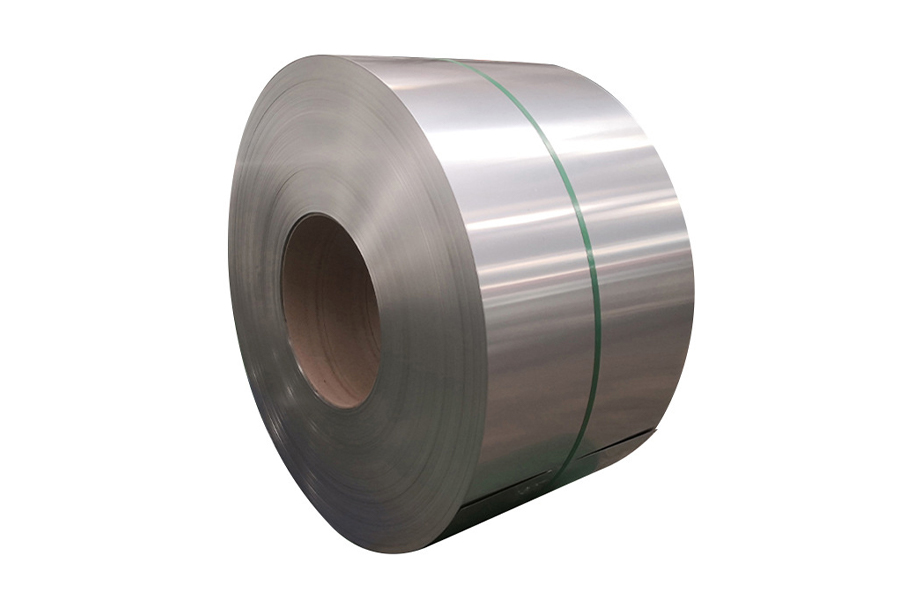

201 cold-rolled stainless steel coil is a widely used material in industrial, construction, and household applications. Known for its high corrosion resistance, durability, and cost-effectiveness, it is an attractive choice for manufacturers seeking reliable stainless steel solutions. This article explores the properties, manufacturing processes, applications, and advantages of 201 cold-rolled stainless steel coil, offering practical insights for engineers, designers, and procurement specialists.

Chemical Composition and Mechanical Properties

The chemical composition of 201 cold-rolled stainless steel coil typically includes approximately 16–18% chromium, 3.5–5.5% nickel, and 5.5–7.5% manganese. Its low nickel content makes it more economical than 304 stainless steel while still maintaining sufficient corrosion resistance in mild environments.

Mechanical Characteristics

201 cold-rolled stainless steel exhibits excellent strength and hardness. Its tensile strength typically ranges from 515–750 MPa, with a yield strength of 205–450 MPa. This makes it suitable for applications requiring moderate load-bearing capacity without compromising flexibility or formability.

Manufacturing Process of Cold-Rolled 201 Stainless Steel

The cold-rolling process improves the surface finish and mechanical properties of stainless steel coils. Cold-rolled 201 stainless steel is produced by:

- Hot-rolling the stainless steel slab to a manageable thickness.

- Cooling the slab and performing surface pickling to remove oxides.

- Cold-rolling to the desired thickness while increasing surface smoothness and tensile strength.

- Annealing to relieve stress and enhance ductility.

- Final finishing such as polishing or coating to achieve the required aesthetic and functional properties.

Surface Finishes and Coating Options

Cold-rolled 201 stainless steel coils are available in various surface finishes including:

- 2B Finish – smooth, standard matte finish for general purposes.

- BA Finish – bright, reflective finish suitable for decorative applications.

- HL Finish – hairline finish for aesthetic interior designs.

- Coated Options – protective films or polymer coatings to enhance corrosion resistance and facilitate handling during fabrication.

Applications of 201 Cold-Rolled Stainless Steel Coil

Thanks to its combination of strength, corrosion resistance, and cost efficiency, 201 cold-rolled stainless steel coil is widely applied across different industries:

Construction and Architecture

Used in building facades, roofing, ceiling panels, handrails, and decorative elements. The 2B or BA finish offers aesthetic appeal while ensuring long-term durability in indoor and outdoor environments.

Home Appliances and Kitchenware

Manufacturers use 201 cold-rolled stainless steel coil for washing machines, refrigerators, water heaters, sinks, and cookware. Its corrosion resistance to moisture and detergents makes it ideal for household applications.

Industrial Equipment

It is frequently used in ductwork, piping, and light industrial machinery. Cold-rolled 201 stainless steel provides strength, surface smoothness, and resistance to mild corrosive environments typical in light industrial settings.

Advantages of Choosing 201 Cold-Rolled Stainless Steel Coil

Selecting 201 cold-rolled stainless steel offers several benefits for manufacturers and engineers:

- Cost-Effective: Lower nickel content reduces overall production costs compared to 304 stainless steel.

- Good Corrosion Resistance: Suitable for indoor and mild outdoor environments.

- High Strength: Offers mechanical performance suitable for structural and industrial applications.

- Formability: Cold-rolled 201 stainless steel is easy to cut, bend, and shape for various fabrication needs.

- Versatile Surface Finishes: Multiple finishes provide both functional and aesthetic flexibility.

Storage, Handling, and Maintenance

Proper storage and handling are crucial to preserving the quality of 201 cold-rolled stainless steel coils. Key considerations include:

- Keep coils in a dry, ventilated environment to avoid surface oxidation.

- Use protective films during transport and storage to prevent scratches.

- Handle coils with care using slings or forklifts to prevent deformation.

- Periodic cleaning with mild detergents and soft cloths helps maintain aesthetic finishes.

Quality Standards and Certifications

201 cold-rolled stainless steel coils are manufactured according to national and international standards to ensure consistent quality. Common standards include ASTM A240, EN 10088, and JIS G4305. Certifications often include ISO 9001 for quality management and SGS inspection for product compliance and chemical composition verification.

Conclusion

201 cold-rolled stainless steel coil is a versatile, cost-effective, and reliable material for industrial, construction, and decorative applications. Understanding its chemical composition, mechanical properties, manufacturing processes, and proper handling ensures optimal performance and longevity in various projects. Selecting the appropriate finish and adhering to quality standards further enhances the efficiency and durability of the final product, making 201 cold-rolled stainless steel coil an ideal choice for engineers, designers, and fabricators seeking both performance and economy.

English

English русский

русский عربى

عربى 中文简体

中文简体